Turn Demolition Debris into Dollars? Our specialized construction waste crusher plants are engineered to tackle the toughest demolition waste on-site. Efficiently crush, sort, and transform heterogeneous debris into valuable, high-demand recycled aggregates – ready for reuse in hours, not days. Please go on reading to discover how targeted crushing turns your waste stream into a revenue stream.

Understanding Construction Waste

Construction waste is categorized into four primary types based on composition and handling requirements:

| Concrete/Brick Debris | Includes demolished concrete structures, bricks, tiles, and masonry (typically 50-70% of total waste). |

| Mixed Inert Waste | Non-hazardous materials like soil, ceramics, and asphalt. |

| Non-Inert Waste | Combustible or biodegradable materials (e.g., timber, plastics, packaging), requiring separation before recycling. |

| Hazardous Waste | Toxic components (e.g., paints, asbestos, solvents) that mandate specialized disposal. |

Processed construction waste converts into recycled coarse/fine aggregates (RCAs) with verified engineering uses:

| Structural Concrete | Up to 30% replacement of natural aggregates in C25-C30 concrete after strength validation. |

| Road Infrastructure | Base/subbase layers for highways and pavements, substituting virgin gravel. |

| Non-Structural Uses | Backfill material, drainage layers, and landscaping substrates. |

| Eco-Friendly Products | Raw material for precast blocks, permeable pavers, and green building components. |

| Source Material | Concrete-rich waste yields higher-grade aggregates; brick/soil mixtures require intensive sorting. |

| Processing | Multi-stage crushing, screening, and contaminant removal (e.g., magnetic separation) are critical to meet impurity thresholds. |

| Performance Trade-offs | Higher absorption (5–10% vs. 0.5–2% for natural aggregates) may reduce concrete workability but is manageable with admixtures. |

Test waste composition before processing—high concrete content enables structural reuse; excess soil/wood necessitates pre-sorting. Global standards converge on safety, impurity control, and performance consistency, enabling cross-border adoption of recycled aggregates.

Equipment Selection & Configuration for Construction Waste Recycling

Choosing the right crushing setup hinges on three critical factors: your waste composition, site mobility requirements, and production goals. We break down key considerations below to match your project needs with optimal solutions.

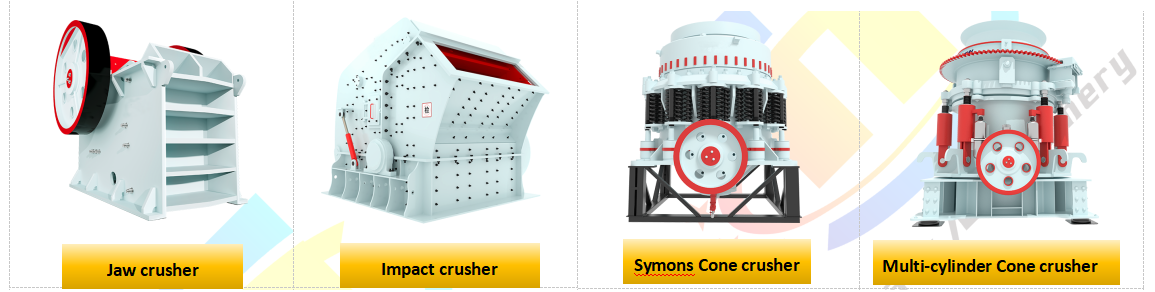

If your waste is primarily concrete (over 70%), we recommend starting with a jaw crusher as the primary unit. Jaw crushers deliver high compression force (250-400 MPa), efficiently breaking reinforced concrete blocks and foundations. For secondary crushing, consider an impact crusher to achieve well-shaped aggregates or a cone crusher if your debris contains highly abrasive elements. Our impact crushers feature heavy-duty rotors and buffer bed discharge designs, extending wear-part life by 30% compared to conventional models.

For mixed debris like bricks, soil, and tiles, anImpact crusher paired with a vibrating screen is ideal. Impact crushers excel at processing heterogeneous materials, while screens remove undersized fines to meet quality standards. All our impact crushers include dual-sealed feed and discharge points, reducing dust emissions by 60% to comply with EU/US particulate regulations.

Zhengzhou Hochang Machinery CO.,Ltd ADD: Hi-Tech Industry Development Zone, Zhengzhou city, China

Email: info@zzhochang.com Offocal Website: www.zzhochang.com Site Map: Sitemap

Here is our best selling product.