【Capacity】:60-250t/h

【Feed Size】:«250mm

【Power】:101-330kW

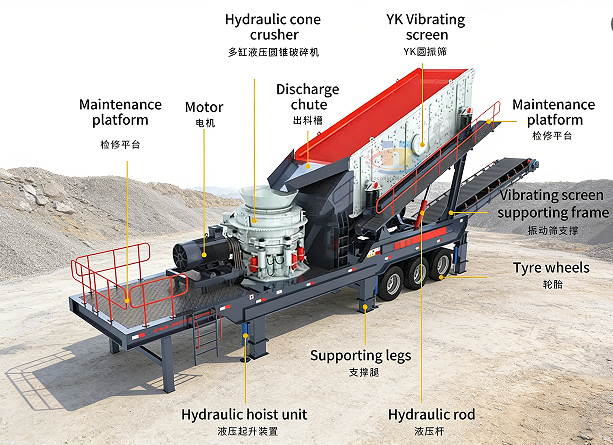

【Application】:Mobile cone crusher is a self-propelled, portable crushing unit that integrates a high-performance cone crusher onto a single chassis.It can be easily relocated around a quarry or between job sites without the need for disassembly and complex installation

| Model | Cone crusher | Screen machine | Belt conveyor | Number of axis | Transportation dimensions (mm) |

| WHC-9018 | HC-917 | 3YK1848 | 800*7 m | 2 | 13920X2780X4300 |

| WHC-1318 | HC-1324 | 3YK1848 | 1000*8m | 3 | 14323X3070X4585 |

| WHC-200 | HP200 | 3YK1860 | 800*8m | 3 | 14323X3070X4585 |

| WHC-300 | HP300 | 3YK2160 | 1000*8m | 3 | 14323X3070X4585 |

Zhengzhou Hochang Machinery CO.,Ltd ADD: Hi-Tech Industry Development Zone, Zhengzhou city, China

Email: info@zzhochang.com Offocal Website: www.zzhochang.com Site Map: Sitemap

Here is our best selling product.