1. Soil and stone separator Introduction

Many mining resources are faced with such a problem, mud and stones mixed together, difficult to separate. Crusher equipment is difficult to bear large humidity of raw materials, not to mention viscous mud? Mud adhesion in the crusher crushing chamber,resulting in equip

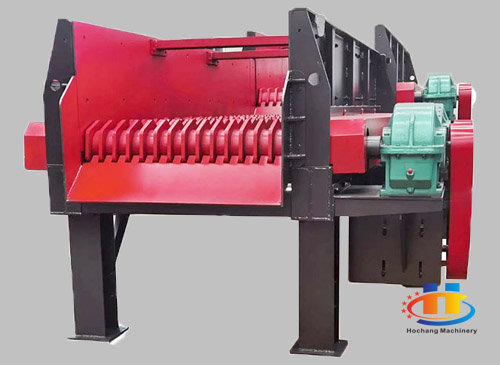

ment shutdown, paralysis, equipment damage. In this case, the separation of mud and stone is the key, how to achieve the rapid separation of mud and stone? Mud and stone separator solves the problem that mud and stone are difficult to separate. It is also called multistage linkage roller screen, which has the characteristics of fast separation speed and no need to use water. It is driven by multi-gear joint, no noise, no dust, and more energy saving. The inner side is inset with guard plate, the shaft plate is cast with manganese steel, and the service life is long. The mudstone separation and screening equipment is used without blocking material, without sticking machine, without winding, and the operation is smooth.

2. Mud and stone separator Application scope

Separation of mud and stone, sand and stone in stone yard, ore separation in mineral processing plant, coal conveying

separation in coal mine, coal gangue separation, construction decoration waste separation, household waste separation, stale waste separation, etc.

3. Structural components

3. Structural components

The main components of the mud and stone separator include: base, motor reducer, coupling, screen roll, sheet, body, chute,electro-hydraulic push rod, electronic control device, etc. The equipment is divided into two forms of centralized transmission and single-roll single-shaft transmission, which can be selected according to customer requirements and mining conditions. When the mudstone separator is running, the raw materials enter the equipment from the upper feeding port, and are screened by the sieve roller drive. The foreign bodies and chunks are discharged through the slag chute, and the qualified materials are discharged from the lower chute.